Product Categories

Product Categories Contact us

Contact usTel:+86-577-62510477 62510577

Fax:+86-577-62510677 62510206

Email:pheuco@vip.163.com sales@pheuco.com

Address:No.2 Ningjin Road Gaizhu Industrial Zone Yueqing City Zhejiang, China

Address:No.2 Ningjin Road Gaizhu Industrial Zone Yueqing City Zhejiang, China

Address2:Haitong Industrial concentration area, Sheyang County, Yancheng City, Jiangsu , China

Address2:Haitong Industrial concentration area, Sheyang County, Yancheng City, Jiangsu , China

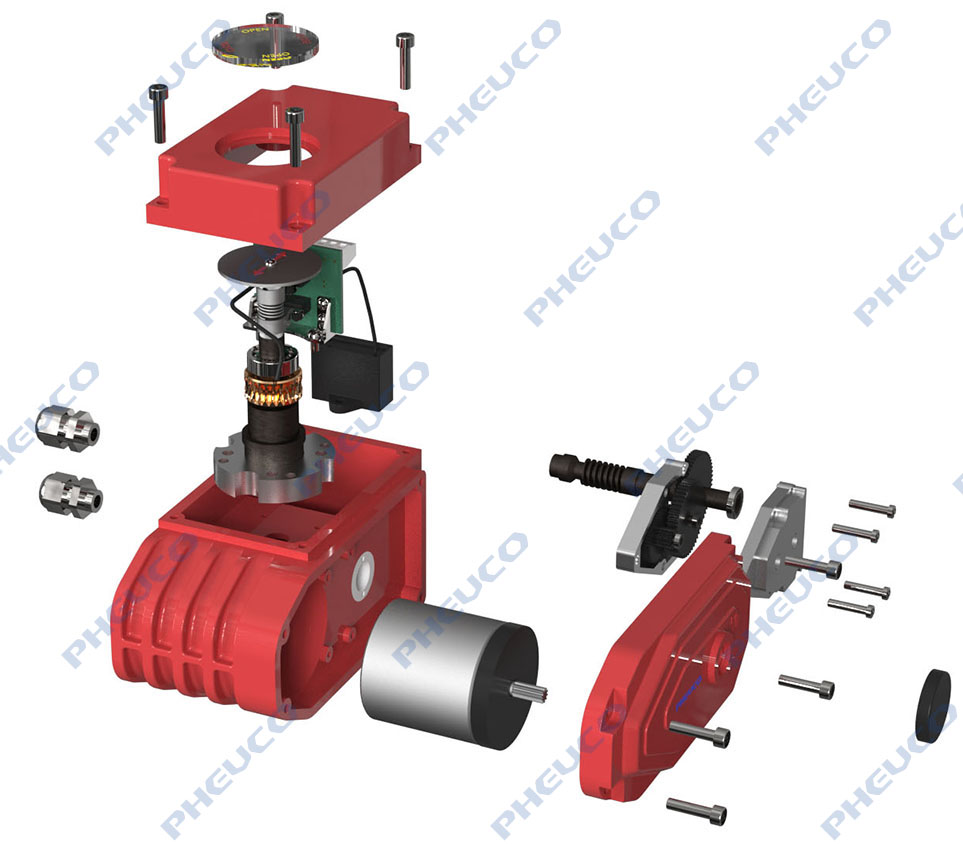

ET series electric actuators are used to control the 0° ~ 270° rotation of electric valves and other similar products, such as electric butterfly valve, electric ball valve, damper, flapper valve, plug valve, louver valve, etc. Widely used in petroleum, chemical, water treatment, shipping, papermaking, power station, heating, building automation, light industry and other industries. It uses AC380V/220V/110V AC power supply as the driving power and 4-20MA current signal or 0-10V DC voltage signal as the control signal, which can make the electric valve move to the desired position and realize its automatic control.

1. The shell is made of hard aluminum alloy, anodized and coated with polyester powder, with strong corrosion resistance. The protection class is IP67, NEMA4 and 6, and IP68 type and explosion-proof type are available for selection.

2. The motor adopts fully enclosed squirrel cage motor, which has the characteristics of small size, large torque and small inertia force. Insulation class H, built-in overheating protection switch, can prevent overheating damage to the motor.

3. Manual structure handle design to ensure safety and reliability, labor saving, small volume. When the power is off, pull the handle for manual operation. When manual use is not required, the wrench is placed in the wrench clip for easy use.

4. Overload protection can be provided. When the valve is stuck and there is a foreign body, the motor power is automatically disconnected, which can more effectively protect the valve and electric actuator from damage. (Standard configuration without over-torque, optional)

5. Precision worm gear and worm mechanism can efficiently transmit large torque, high efficiency, low noise (maximum 50 dB), long life; Self - locking function, prevent reversal, the transmission part is stable and reliable, no need to refuel.

6. The bottom installation size conforms to ISO5211 international standard, the driving shaft sleeve can be removed according to the need for processing, strong adaptability. It can be installed vertically or horizontally.

7. The control line conforms to single-phase or three-phase power supply standard, the line layout is compact and reasonable, and the terminal can effectively meet the requirements of various additional functions.

Chinese

Chinese